intelligent weld monitoring and management system

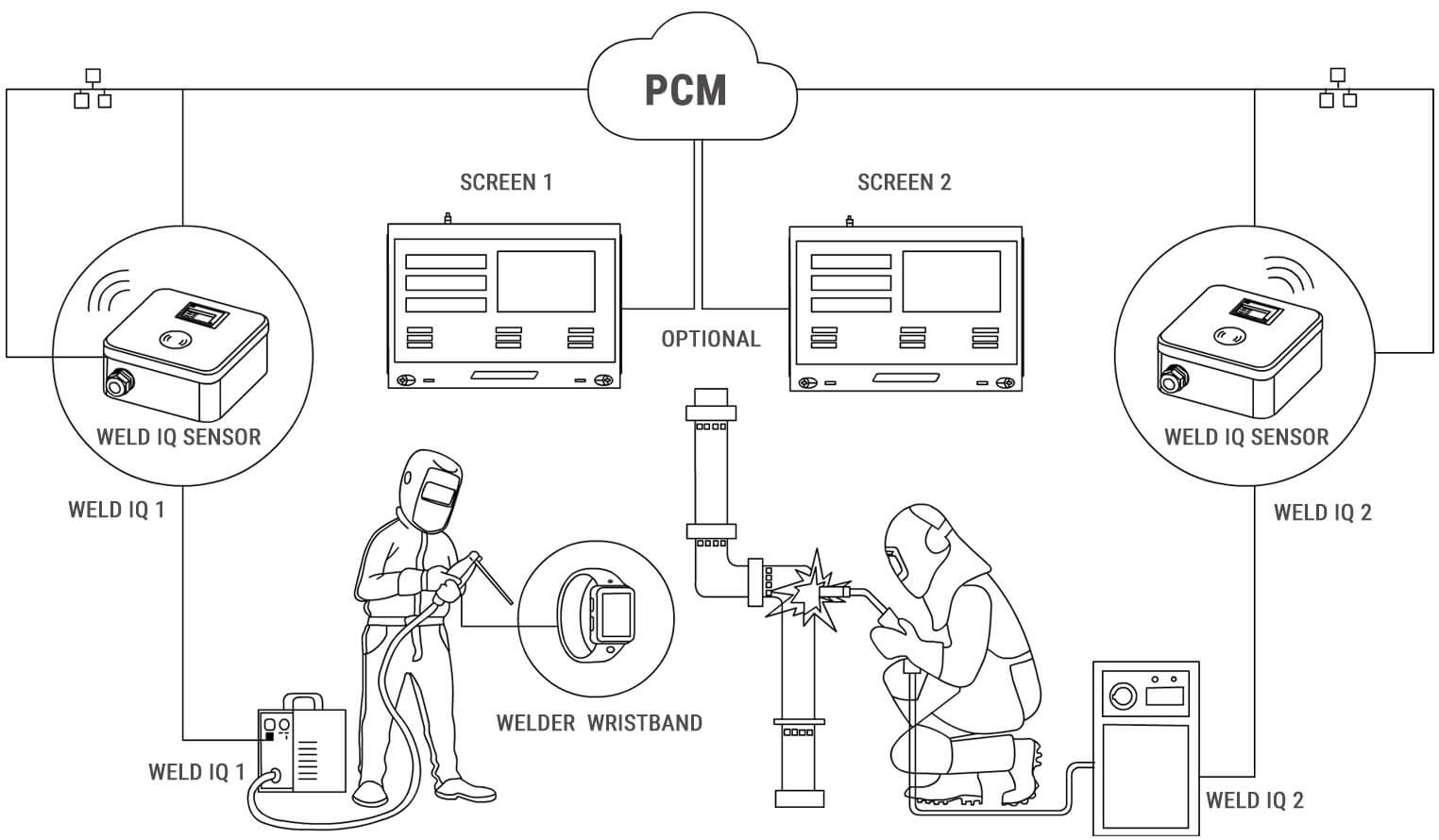

An intelligent performance monitoring sensor called Weld IQ is a real time sensor capable of measuring, storing and transmitting welder performance data. It measures machine usage of welders and the data is processed by an intelligent software application called PCM suite for measuring productivity.

PCM (Project Control & Management) is a web based application which evaluates the fabrication project’s performance in relation to project baselines, with instant comparison of planned vs actual man-hours. It helps the project management teams to plan, monitor, optimise, quality check and report all weld related information. An intelligent dashboard displays KPI’s (Key Performance Indicators) using the latest in data visualisation technology.

results and outcomes

REAL TIME MONITORING OF ALL WELDING PROCESSES AND EARLY FAULT DETECTION

Realtime visibility of project progress

Create detail project plans, allocate welds based on welder qualification and track project progress. No more costly delays.

Welder identification & intelligent work allocation

Each welder is given an RFID wristband. The Weld IQ sensor then checks and allocates the right weld based on welder’s qualification and job allocation.

Decrease NDT without reducing quality

Inbuild Artificial intelligence continuously monitors welder performance and weld quality. Anomalies like Spot welds are instantly identified with clear audit trail of each weld. Its Machine Learning algorithm reduces NDT and QA/QC requirement with improvement in quality.

PLAN, ALLOCATE AND CONTROL ALL YOUR FABRICATION ACTIVITIES THROUGH A CENTRAL SYSTEM

Implement our cloud based Project Control & Management (PCM) system to control your fabrication process and get clear visibility in all your project. It manages your weld procedures, drawings, personnel files and qualifications in one unified system. Tasks such as weld allocation based on qualification and experience can be easily assigned. Management teams can monitor project progress in real time and quickly identify bottlenecks early enough for an on time project completion.