A METAVERSE

CREATING PARALLEL WORLDS WITH IoT SENSORS & AI DIGITAL TWINS

HyperTwin AI is a Metaverse platform for your digital twin.

Navigate in this ultra-realistic virtual world and perform activities with out leaving the comfort of your home.

There is no more work place commute, long journey, traffic jams with high carbon emissions. Virtually visit your workplace and meet other avatars or interact with real people as if they are in front of you !

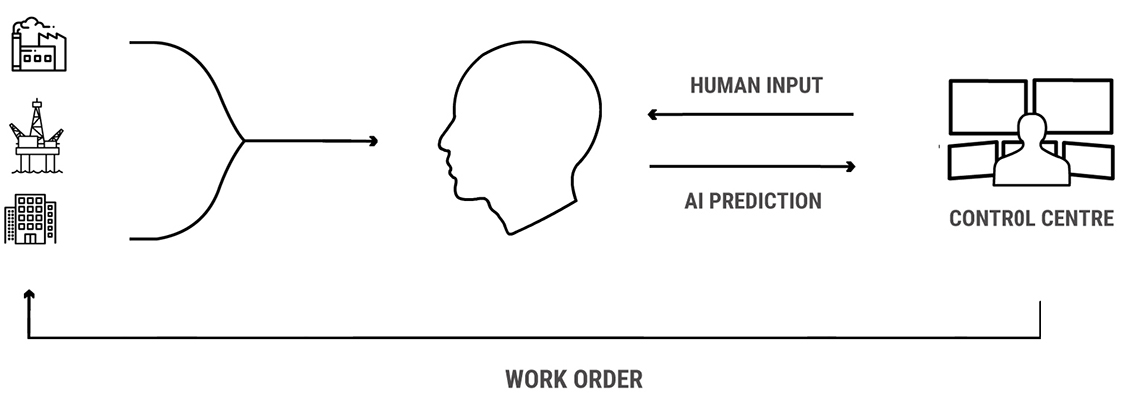

Its AI powered sensor networks connects every one and everything together….from people to equipment.

Repairs orders or maintenance activity can now be done remotely by any expert globally with the right skill set and knowledge. No more long and costly down time waiting for the right person to turn up

HyperTwin monitors, learns and optimises people, process and assets across your whole ecosystem..

Welcome to this new world where there are no boundaries

HyperTwin AI + ML

results and outcomes

get real insight using HYPERTWIN AI machine learning technology for maximising asset performance

Improve uptime

Reduce equipment trips and unplanned shutdowns by applying Machine Learning models to your complex data for predictive alerts and increased visibility.

See it before it happens !

Reduce personnel cost & time

Achieve deeper and real time operational know how and identify component failure. Mobilise the right resource and spares. Decrease OPEX and reduces excesses spare part inventory.

Enhance asset performance

Using our accurate 3D Digital Twin to seamlessly interact with your physical asset to visualise, monitor and control the asset remotely.